Introduction

The Internet of Things (IoT) and the Digital Twin Technology have changed the ways the physical and digital worlds interact. In this regard, their combined synergy is a potent fusion that is shaping the future of businesses worldwide.

Internet of Things describes the network of physical objects – “things” – that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.

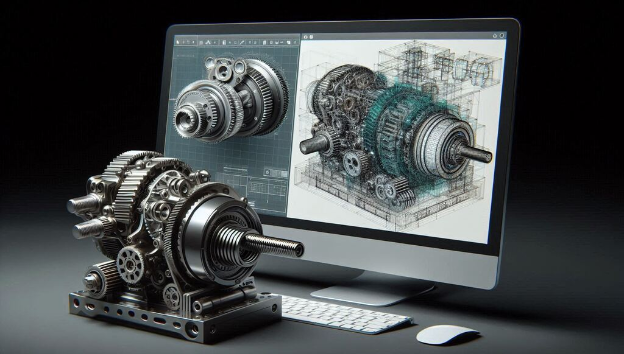

Digital twins are virtual replicas of physical devices that IT pros and data scientists can use to run simulations before actual devices are built and deployed.

IoT by itself is useful, but the sheer amount of data can be overwhelming. Digital twins break down the information into understandable categories – people, products, places, processes – that are more immediately clear and understandable.

Thus an IoT Digital Twin is a digital representation of a real-world entity, such as a device or a manufacturing production process connected to the internet. Such connected digital twins can then be used for various purposes, for example predicting scenario-based outcomes.

As IoT devices are further refined, digital-twins can be made of smaller and less complex objects, giving additional benefits to companies. These devices can range from ordinary household objects to sophisticated industrial tools.

So, now, let us explore more features of the merging of IoT and Digital Twins.

How are Digital Twins leveraging IoT?

Data Collection: IoT devices provide real-time measurements, data of which can be represented by their virtual counterparts. These can then help understand what the outcomes might be in various scenarios. The number of data sources can also be many, which can be collated to generate a wholesome picture.

Feedback Loop and Continuous Iteration: The IoT Digital Twin setup, allows automatic optimization of workflows. Depending on the external weather conditions, for example the angle of the blades of a wind turbine can be adjusted to maximize energy generation.

Predictive Maintenance: Sensors setup near machine components can be used to feed data to the digital twin and computational system, to warn about structural failures and upcoming repairs.

Virtual Prototyping & Testing: The digital twin of a new component can be tried out first in a virtual setup, created by data from IoT sensors, before introducing the real component in the environment. This prevents accidental costs. Employees can also be trained with the digital twin, before the real exercise.

Enhanced User Experience & Personalization: IoT devices can be used to measure consumer metrics. The data can then be fed to the digital twin representation, and the customization of service for the user can be synthesized.

Integration with Other Systems: Digital Twins of devices can interact with those of others, to optimize service. For example, the Digital Twin of a traffic system might interact with that of a public transport system, using real-time IoT data from both.

The Future of Digital Twins & IoT

Let us now see the prospective future of the combination of these two fields:

Granular Digital Replicas: With computational capacity increasing day by day, more sophisticated digital twins can be created. Bigger processes can also be modeled. With the combination of better IoT sensors, better predictive analysis can be done.

Expansion into New Sectors: Presently, these technologies are used in industries like manufacturing, energy, and healthcare. There will likely be an expansion into new sectors, like agriculture, education, and entertainment. Farmers, for instance, can have a digital twin of their farm.

Merging with Other Technologies: Digital Twins and IoT can be combined with AI, to automate decision-making. There can also be a combination with VR/AR, where you could walk into a factory and have digital twins overlaid on the real machines.

Environment and Sustainability: Digital Twins with IoT sensors can be used to simulate entire ecosystems, for study and monitoring. Endangered species can be modeled and observed. Renewable energy generators can be optimized for maximum output.

Enhanced Connectivity: IoT devices and Digital Twins, will allow monitoring of entire processes of businesses in the palm of the hand. Devices can talk to one another, to optimize workflows.

Conclusion

The digital twin technology is among the most rapidly evolving Industry 4.0 technologies. With the increasing popularity of IoT and increasing sophistication of the business landscape, many industries have started implementing digital twins.

As IoT continues to evolve, digital twin technology will also permeate everywhere. Continuously trying to find new pathways for the combining of the fields of IoT and Digital Twins will have profound implications on the world of business. It will also improve the personal lives of the common people, empowering them and giving them more control over the devices they use.

AI Generated Image